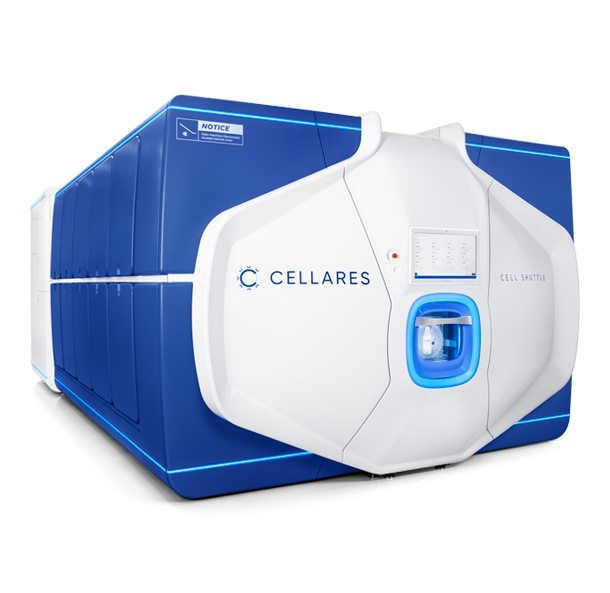

Fully Integrated, Scalable, cGMP Cell Therapy Manufacturing Platform

HIGH THROUGHPUT MANUFACTURING

Purpose-built Technology Powers the First Integrated Development & Manufacturing Organization (IDMO)

Reagent Vault System (RVS)

- Capacity for up to 200 automation-friendly reagent bottles (SLTDs)

- SLTDs come in three volumes: 10mL, 50mL, 1000mL

- Reagent agnostic (all vendors supported)

- Refrigerated at 4°C

- Just in time lane for time critical reagent delivery

- Integrated software for reagent scheduling, inventory and supply chain management

- All SLTDs undergo hydrogen peroxide decontamination cycles

Reagent Vault System (RVS)

- Capacity for up to 200 automation-friendly reagent bottles (SLTDs)

- SLTDs come in three volumes: 10mL, 50mL, 1000mL

- Reagent agnostic (all vendors supported)

- Refrigerated at 4°C

- Just in time lane for time critical reagent delivery

- Integrated software for reagent scheduling, inventory and supply chain management

- All SLTDs undergo hydrogen peroxide decontamination cycles

4x Sterile Liquid Transfer Systems (SLTS)

- Facilitates mating of Cellares’ Consumable Cartridge and automation friendly reagent bottles (SLTDs)

- Performs all sterile liquid transfer operations including reagent addition and sampling

4x Sterile Liquid Transfer Systems (SLTS)

- Facilitates mating of Cellares’ Consumable Cartridge and automation friendly reagent bottles (SLTDs)

- Performs all sterile liquid transfer operations including reagent addition and sampling

Material Handling System (MHS)

- Automates the transfer of Consumable Cartridges (CC) and automation-friendly reagent bottles (SLTDs)

- Transfers occur between feedthroughs, reagent vault system (RVS) and instruments (BPS and SLTS)

Material Handling System (MHS)

- Automates the transfer of Consumable Cartridges (CC) and automation-friendly reagent bottles (SLTDs)

- Transfers occur between feedthroughs, reagent vault system (RVS) and instruments (BPS and SLTS)

16x Bioprocessing Systems (BPS)

- Counterflow Centrifugal Elutriation (CCE)

- Magnetic Selection (MS)

- Electroporation (EP)

- Bioreactor System (BRS)

16x Bioprocessing Systems (BPS)

- Counterflow Centrifugal Elutriation (CCE)

- Magnetic Selection (MS)

- Electroporation (EP)

- Bioreactor System (BRS)

Integrated and Flexible Software Suite

- Process Design Studio supports 90% of cell therapy modalities (auto & allo) in a single cartridge design

- Integrated MES allows for batch scheduling across Cell Shuttle fleet

- Real-time process monitoring solution

- Auto-generation of electronic batch records

- Integrates with 3rd party software systems (ERP, MES, LIMS)

Integrated and Flexible Software Suite

- Process Design Studio supports 90% of cell therapy modalities (auto & allo) in a single cartridge design

- Integrated MES allows for batch scheduling across Cell Shuttle fleet

- Real-time process monitoring solution

- Auto-generation of electronic batch records

- Integrates with 3rd party software systems (ERP, MES, LIMS)

Cell Shuttle Feedthrough

- Up to 16 cartridges can be loaded asynchronously for multi-product, concurrent manufacturing

- Each cartridge can run a different cell therapy process as defined in the Process Design Studio

- Each cartridge can produce a different batch/product

- The feedthrough is the entry and exit point for all Consumable Cartridges

- All cartridges undergo hydrogen peroxide decontamination cycles

Cell Shuttle Feedthrough

- Up to 16 cartridges can be loaded asynchronously for multi-product, concurrent manufacturing

- Each cartridge can run a different cell therapy process as defined in the Process Design Studio

- Each cartridge can produce a different batch/product

- The feedthrough is the entry and exit point for all Consumable Cartridges

- All cartridges undergo hydrogen peroxide decontamination cycles

Cell Shuttle Sterility Paradigm

- Each batch/product has a dedicated set of pre-sterilized automation-friendly reagent bottles (SLTDs) and one Consumable Cartridge. Each of these consumable sets constitutes a closed system

- The Cell Shuttle maintains an internal ISO8 cleanroom environment

- The Cell Shuttle can be deployed in controlled not-classified environments (CNC)

- All consumables undergo hydrogen peroxide decontamination cycles as they enter the feedthrough or the reagent vault system (RVS)

Cell Shuttle Sterility Paradigm

- Each batch/product has a dedicated set of pre-sterilized automation-friendly reagent bottles (SLTDs) and one Consumable Cartridge. Each of these consumable sets constitutes a closed system

- The Cell Shuttle maintains an internal ISO8 cleanroom environment

- The Cell Shuttle can be deployed in controlled not-classified environments (CNC)

- All consumables undergo hydrogen peroxide decontamination cycles as they enter the feedthrough or the reagent vault system (RVS)

-

16 batches processed in parallel

-

75% fewer process failures

-

90% less labor required

-

90% less facility space required

-

The majority of modalities supported (auto & allo)

“Cellares’ revolutionary technology will be a game changer for the cell therapy industry.“

INTEGRATED AUTOMATION

Truly Closed and Automated from End-To-End

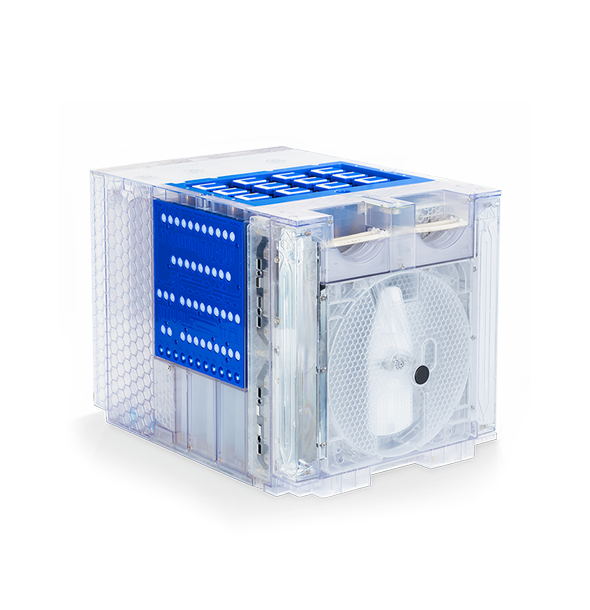

Electroporators (EP)

- Achieves world-class EP efficiency

- All EP parameters are customizable via Process Design Suite which enables EP optimization

- Supports all common genetic modification technologies (CRISPR, TALEN, ZFN) and reagents

- Ability to electroporate infinite number of cells via automated batch processing

Electroporators (EP)

- Achieves world-class EP efficiency

- All EP parameters are customizable via Process Design Suite which enables EP optimization

- Supports all common genetic modification technologies (CRISPR, TALEN, ZFN) and reagents

- Ability to electroporate infinite number of cells via automated batch processing

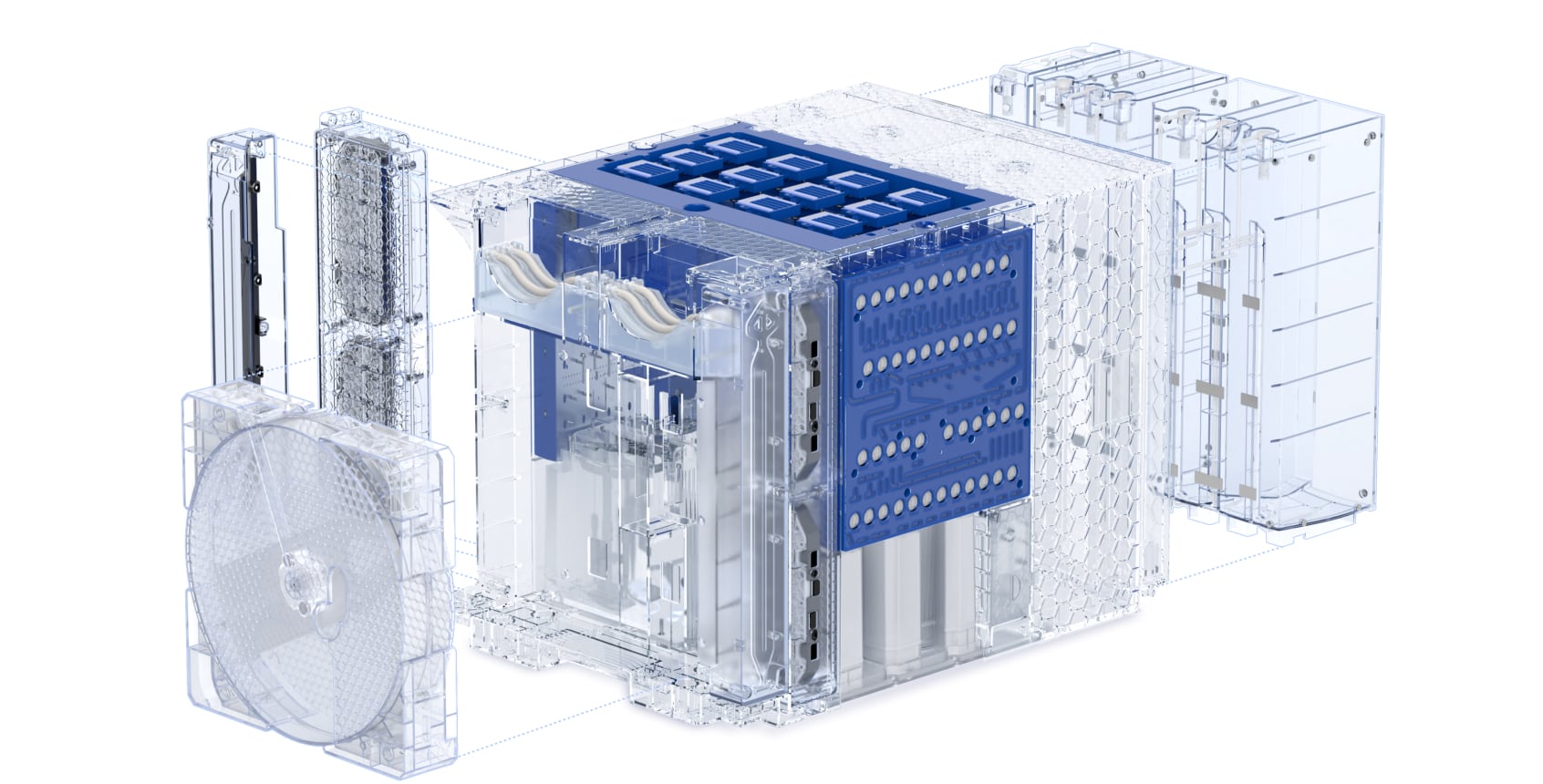

Peristaltic Pumps

- Multiple peristaltic pumps enable multiple process steps to run in parallel on the same cartridge

- Pump interfaces are used to facilitate sterile, metered liquid transfer between internal cartridge modules and automation friendly reagent bottles (SLTDs)

Peristaltic Pumps

- Multiple peristaltic pumps enable multiple process steps to run in parallel on the same cartridge

- Pump interfaces are used to facilitate sterile, metered liquid transfer between internal cartridge modules and automation friendly reagent bottles (SLTDs)

Fluidic Bus

- Integrated valves, sensors, fluid channels, and pumps automate all internal fluid transfers

- The Fluidic Bus enables reagent transfers from any module of the cartridge to any other module

- The modularity of the Fluidic Bus enables support for the majority of cell therapy modalities (auto & allo) within the same cartridge design

Fluidic Bus

- Integrated valves, sensors, fluid channels, and pumps automate all internal fluid transfers

- The Fluidic Bus enables reagent transfers from any module of the cartridge to any other module

- The modularity of the Fluidic Bus enables support for the majority of cell therapy modalities (auto & allo) within the same cartridge design

Reagent & Final Product Containers

- Smart containers provide precise, real-time volume tracking

- Integrated smart containers for starting material, reagent storage and final product formulation

Reagent & Final Product Containers

- Smart containers provide precise, real-time volume tracking

- Integrated smart containers for starting material, reagent storage and final product formulation

Bioreactor System (BRS)

- Supports expansion of >20 billion cells

- Perfusion-enabled stirred-tank design

- Closed loop control and real-time monitoring of temperature (T), dissolved oxygen, (DO) and acidity (pH)

Bioreactor System (BRS)

- Supports expansion of >20 billion cells

- Perfusion-enabled stirred-tank design

- Closed loop control and real-time monitoring of temperature (T), dissolved oxygen, (DO) and acidity (pH)

Sterile Liquid Transfer Ports (SLTP)

- Supports reagent additions, waste removal and automated sampling

- SLTPs on the Consumable Cartridge (CC) interface with the SLTPs on the automation-friendly reagent bottles (SLTDs)

- The Sterile Liquid Transfer System (SLTS) facilitates metered, automated, sterile liquid transfer into and out of the Consumable Cartridge

Sterile Liquid Transfer Ports (SLTP)

- Supports reagent additions, waste removal and automated sampling

- SLTPs on the Consumable Cartridge (CC) interface with the SLTPs on the automation-friendly reagent bottles (SLTDs)

- The Sterile Liquid Transfer System (SLTS) facilitates metered, automated, sterile liquid transfer into and out of the Consumable Cartridge

Magnetic Cell Sorter (MS)

- Supports magnetic selection with both microbeads and nanobeads (reagent agnostic)

- Supports both positive and negative selection

- Column-free design operates in batch mode to process any volume of cells

Magnetic Cell Sorter (MS)

- Supports magnetic selection with both microbeads and nanobeads (reagent agnostic)

- Supports both positive and negative selection

- Column-free design operates in batch mode to process any volume of cells

Counterflow Centrifugal Elutriator (CCE)

- Operates in batch mode to process any volume of cells

- Can be used at arbitrary times in the workflow as defined in the Process Design Studio

Counterflow Centrifugal Elutriator (CCE)

- Operates in batch mode to process any volume of cells

- Can be used at arbitrary times in the workflow as defined in the Process Design Studio

The integrated Consumable Cartridge reduces process failure rates by 75%

- Automation eliminates opportunities for operator error

- Closing the process eliminates opportunities for contamination

-

ENRICHMENT

-

BUFFER EXCHANGE

-

CONCENTRATION

-

SAMPLING

-

IN-PROCESS QC

-

SELECTION

-

ACTIVATION

-

TRANSDUCTION

-

TRANSFECTION

-

EXPANSION

-

FORMULATION

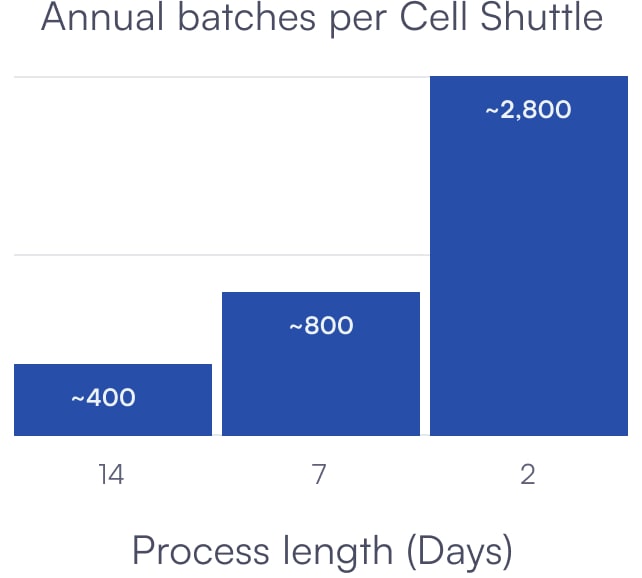

SCALABILITY

Enabling Commercial Scale Manufacturing of Cell Therapies

-

Integrated Automation

All unit operations in one Consumable Cartridge

-

High Throughput

Up to 16 cartridges for multi-product, concurrent manufacturing

-

Scalability

Up to 2,800 batches per Cell Shuttle per year

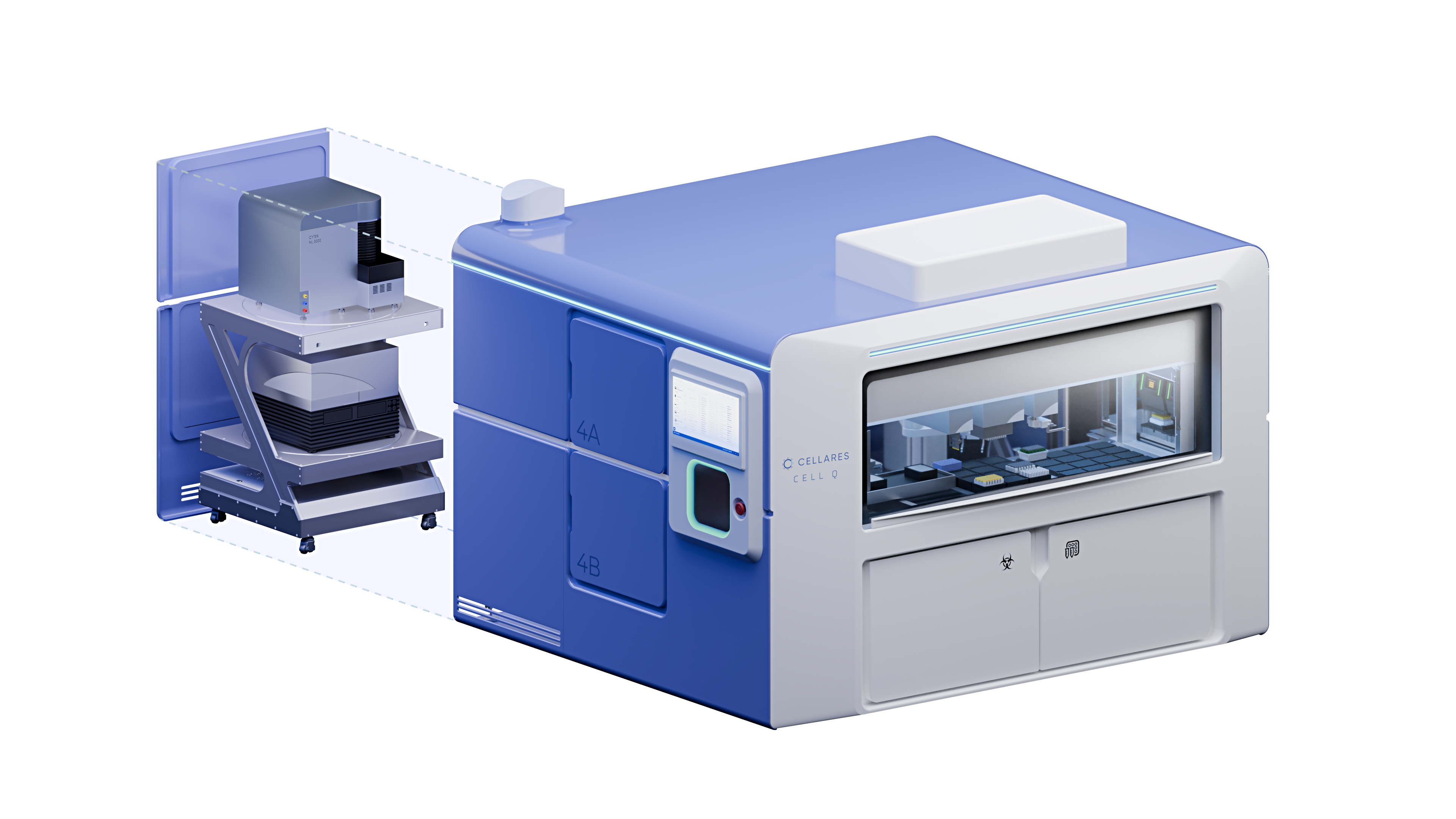

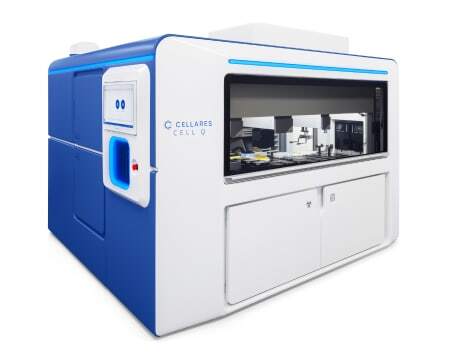

Fully Automated, Scalable, cGMP Cell Therapy QC Platform

High Throughput QC

Integrates & Automates Off-the-Shelf, Industry Standard QC Instrumentation

Modular Instrument Carts

- Integrates industry standard, off-the-shelf QC instrumentation to automate the vast majority of in-process and release assays

- Allows for interchange of instrumentation enabling customized workflows

- Minimizes workcell downtime by providing rapid replacement of pre-qualified instruments

Modular Instrument Carts

- Integrates industry standard, off-the-shelf QC instrumentation to automate the vast majority of in-process and release assays

- Allows for interchange of instrumentation enabling customized workflows

- Minimizes workcell downtime by providing rapid replacement of pre-qualified instruments

Fully Integrated IDMO Data Stack

- Supports auto-generation of electronic batch records (EBRs)

- Enables real-time manufacturing process monitoring

Fully Integrated IDMO Data Stack

- Supports auto-generation of electronic batch records (EBRs)

- Enables real-time manufacturing process monitoring

Feedthrough

- Entry point for all samples either in SLTD format or standard cryotubes

- Can process multiple samples from multiple batches concurrently

- Barcode scanning of all samples and reagents ensures maintenance of chain of identity and chain of custody

Feedthrough

- Entry point for all samples either in SLTD format or standard cryotubes

- Can process multiple samples from multiple batches concurrently

- Barcode scanning of all samples and reagents ensures maintenance of chain of identity and chain of custody

Cell Q Workcell

- Fully enclosed, cGMP QC workcell maintains sample sterility

- Hatches provide easy access for consumable and reagent addition as well as waste removal

Cell Q Workcell

- Fully enclosed, cGMP QC workcell maintains sample sterility

- Hatches provide easy access for consumable and reagent addition as well as waste removal

Integrated Liquid and Plate Handlers

- Liquid and plate handlers transfer samples and reagents between assay plates and instruments

- Automated sample handling improves reliability and reproducibility of assays via liquid volume detection and other feedback mechanisms

Integrated Liquid and Plate Handlers

- Liquid and plate handlers transfer samples and reagents between assay plates and instruments

- Automated sample handling improves reliability and reproducibility of assays via liquid volume detection and other feedback mechanisms

-

Up to 6,000 batches per year

-

Enables up to 50% lower price per batch

-

Automates the majority of cell therapy QC assays

-

Auto-generates electronic batch records

-

Pre-qualified assays accelerate analytical transfer

UNCAPPED CAPACITY

High-Throughput Manufacturing Requires High-Throughput QC

Automated High-Throughput Manufacturing

Cell Shuttles

Samples transferred via SLTDs*

Cell Q

Automated High-Throughput QC

*Automation-friendly reagent bottles

FLEXIBLE SOFTWARE

Integrated Software Suite Supports the Majority of Cell Therapy Modalities

-

SUPPORTED APPLICATIONS

- Autologous & Allogeneic

- CAR-T, TCR, HSC, NK, TIL, Treg, γδ T cells

-

FLEXIBLE SOFTWARE

- Process customization via Process Design Studio

- Enables digital process development and DOE

-

INTEGRATED HARDWARE

- Every process uses the same modular Consumable Cartridge

- No hardware customization required, which accelerates technology adoption

IDMO ADVANTAGE

Software & Hardware Integration Enable the IDMO Advantage

-

ERP

-

Cell Shuttle

-

Cell Q

-

QC LIMS

-

Electronic Batch Records

-

Scalability

Meet Total Patient Demand Globally with Unconstrained Capacity -

Cost Savings

Up to 50% Reduction in Batch Prices -

Speed

Up to 50% Faster to IND & BLA and Accelerated Global Reach